Plastic Manufacturing

Safe handling of plastic powders, granules, and pellets in injection molding and extrusion processes.

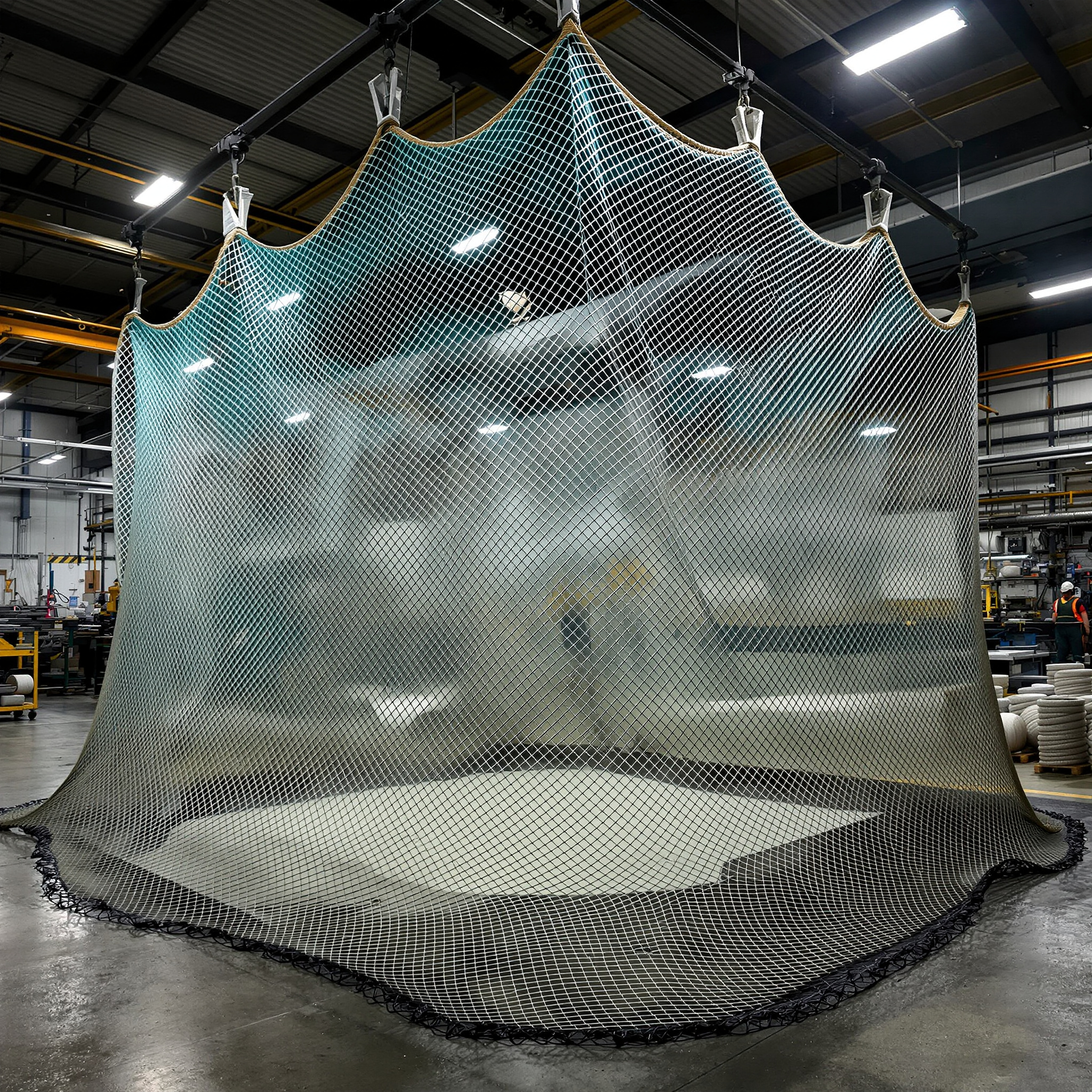

Compression Couplers

Price Available on Request

Detailed technical specifications for our Compression Couplers designed for reliable tube joining applications.

Our Compression Couplers deliver superior tube joining solutions with precision engineering and robust construction for industrial applications.

Large selection of compression couplings to accommodate various tube sizes and system requirements, ensuring the perfect fit for your application.

Available in 2, 3, 4, or 5 bolt styles to match your specific installation requirements and provide optimal coupling strength and reliability.

Engineered for reliable joining of tube sections in tubing systems, providing leak-proof connections and long-lasting performance in demanding applications.

Comprehensive size range from 1-1/2" through 14" OD tube sizes, accommodating both small-scale and large industrial tubing system requirements.

Stay informed about new products, technical guides, and industry solutions.

From automotive to electronics, our accessories deliver precision cooling solutions for every injection molding application.

Safe handling of plastic powders, granules, and pellets in injection molding and extrusion processes.

Optimized cooling processes and cycle time reduction for high-volume injection molding operations with precise temperature control.

Specialized cooling solutions for extreme temperature molding applications requiring precise flow regulation and thermal management.

SMED implementation support with quick ejector systems for efficient mold changeovers and minimized downtime in production.

Discover how our compression couplers have enhanced tubing system reliability and performance for manufacturers worldwide.

The compression couplers from Star Automation have significantly improved our tubing system reliability. The multiple bolt configurations give us flexibility in our installations.

Engineering Manager, AutoParts Inc

The wide size range from 1-1/2" to 14" OD covers all our tubing needs. Star Automation's couplers provide consistent performance across our entire production line.

Plant Manager, TechSystems

Star Automation's technical team helped us select the right coupler configuration for our application. Their expertise and support throughout the installation process was invaluable.

Maintenance Supervisor, Industrial Solutions

We've been using Star Automation's compression couplers for over three years now. The consistent quality and durability have reduced our maintenance costs significantly.

Operations Director, ManufacturePro

The training and implementation support provided by Star Automation made our installation process smooth. Their team understands our needs before we even explain them.

Technical Lead, PrecisionWorks

The compression couplers deliver excellent value for money. The quality construction and reliability have improved our overall system efficiency and reduced downtime.

Procurement Manager, FlexManufacturing

A wide range of equipment designed to enhance efficiency, safety, and performance.

Large selection of tubing ranging from 1-1/2" through 10" OD, available in Carbon, Stainless Steel, and Aluminum materials for diverse industrial applications.

Large selection of TEE's and Mitered 90° fittings, available in Carbon, Stainless Steel, and Aluminum for comprehensive tubing system connections.

Cam-Lock adapters and couplers ranging in size from 1-1/2" through 6", available in Aluminum, Hard Coat Aluminum, and Stainless Steel with precision part numbering system.

Our technical experts can help design the perfect tubing system configuration for your specific requirements.

Ready to enhance your tubing systems with reliable compression couplers? Get in touch with our team for expert guidance and custom quotes.

For immediate assistance, feel free to give us a direct call at (952) 546-6682 You can also send us a quick email at [email protected]

For immediate assistance, feel free to give us a direct call at (952) 546-6682 You can also send us a quick email at [email protected]