Plastic Manufacturing

Safe handling of plastic powders, granules, and pellets in injection molding and extrusion processes.

Self-Cleaning FF Drawer Magnets

Price Available on Request

Detailed specifications for our Self-Cleaning FF Drawer Magnets to help you make informed decisions.

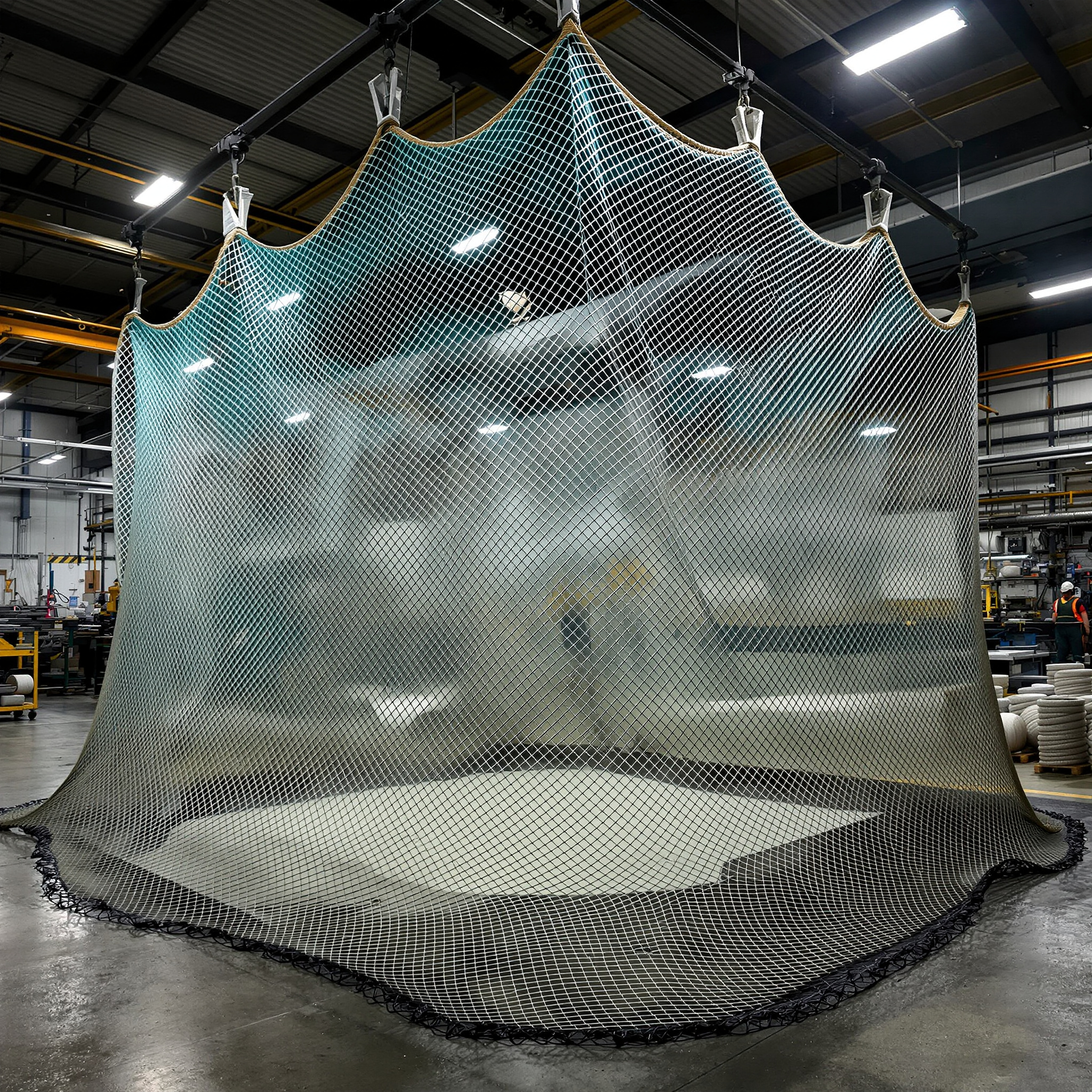

Our Self-Cleaning FF Drawer Magnets deliver superior metal separation with innovative features designed for industrial applications.

Self-cleaning mechanism with one smooth motion eliminates the need to disassemble components, saving time and reducing maintenance costs while ensuring optimal performance.

High-intensity rare earth magnets provide superior magnetic strength for effective separation of ferrous materials from non-ferrous products in your production line.

Welded stainless steel housing ensures long-lasting durability and easy cleaning, making it ideal for harsh industrial environments and food-grade applications.

Minimizes good product loss through efficient separation design and detachable tramp tray that prevents messy cleanups and material spillage during operation.

Available with optional transitions for round or square spouting and pneumatic self-cleaning systems for hard-to-reach installations, ensuring versatile application.

Built to meet demanding industrial standards with proven reliability in plastics manufacturing, injection molding, and material handling applications across various industries.

Get the latest product information and technical resources delivered to your inbox.

From automotive to electronics, our accessories deliver precision cooling solutions for every injection molding application.

Safe handling of plastic powders, granules, and pellets in injection molding and extrusion processes.

Optimized cooling processes and cycle time reduction for high-volume injection molding operations with precise temperature control.

Specialized cooling solutions for extreme temperature molding applications requiring precise flow regulation and thermal management.

SMED implementation support with quick ejector systems for efficient mold changeovers and minimized downtime in production.

Hear from industrial professionals who trust Star Automation for their metal separation needs.

The self-cleaning feature has dramatically reduced our maintenance downtime. We can clean the magnets quickly without stopping production, which has improved our overall efficiency by 30%.

Production Manager, ABC Plastics

The rare earth magnets provide exceptional separation power. We've seen a significant reduction in metal contamination in our final products, which has improved our quality control standards.

Quality Engineer, Industrial Solutions

The stainless steel construction has held up incredibly well in our harsh production environment. The detachable tramp tray makes cleanup so much easier than our previous systems.

Maintenance Supervisor, Tech Manufacturing

Star Automation provided us with custom transitions for our unique spouting system. Their engineering team understood our needs and delivered a solution that integrated perfectly with our existing equipment.

Plant Engineer, Advanced Molding Corp

From initial consultation to installation training, Star Automation's support has been exceptional. They truly understand our industry and provide solutions that work in real-world applications.

Operations Director, Precision Parts Inc

Since installing these magnets, we've seen a measurable improvement in our final product quality. The magnetic separation is so effective that we rarely find any metal contamination in our output anymore.

Quality Manager, Polymer Technologies

A wide range of equipment designed to enhance efficiency, safety, and performance.

Temperature-compensated rare earth magnets with rugged stainless steel housing, supporting 10,000-pound compression loads and featuring heat-resistant EPDM gaskets for superior high-temperature operation.

Designed with an ultra-compact profile of just 5-11/16″ overall height, these drawer magnets fit easily into space-constrained installations. Temperature-compensated rare earth magnets deliver consistent magnetic strength, while the rugged construction supports compression loads up to 10,000 pounds.

Our experts can help design the perfect magnetic separation system for your specific application.

Ready to improve your production efficiency with our magnetic separation solutions? Get in touch with our team today.

For immediate assistance, feel free to give us a direct call at (952) 546-6682 You can also send us a quick email at [email protected]

For immediate assistance, feel free to give us a direct call at (952) 546-6682 You can also send us a quick email at [email protected]